In the recent past, digitizing for embroidery has become an alluring thing. Many individuals are venturing into this business either because it is their hobby or wants to earn a living. This business is easier to even start at home. However, if you want to go into it the large scale way, then you need a talented team and the best software for the embroidery machine.

As everything is moving from analogue to digital, digitizing for embroidery is fast becoming the way to go for most individuals. With this in mind, embroidery digitizing companies are in stiff competition as to who provides the best services and in the process net more customers. A good company should always be able to provide Vector art creation as well. If you are thinking of joining the embroidery digitizing services, then there a few things that you need to put into consideration:

You can also know: [How to choose the right embroidery digitizing with cheapest digitizing service]

Digitizing for Embroidery- Getting the Best Embroidery Machine

The type of embroidery machine depends on the size of your business. If you are starting from your home, then a 15 needle single head machine is ideal for you. However, if you decide to go into this business commercially, then you will need a bigger machine like a two head, four head or even a six head industrial embroidery machine. You might even need several of these machines.

Before embarking on the digitizing for embroidery business, first, you need to select your preferred niche: it could be monogrammed, screen printing, t-shirt printing or any other commercial embroidery business. With this in mind, you will be able to make an informed decision on which machine to buy.

You should always compare reviews and rating on different embroidery digitizing machines. This way you will get to know which company offers services like; training, delivery and after-sale services.

After settling on the type of embroidery machine to buy, now the next question is; should you buy a new or used machine? If this is going to be your first machine, then it is recommended to buy a new machine: the reason being it always comes with a warranty and is most likely to be the latest version which means it has the best features. However, if you cannot afford a new machine, a used one is still fine to start with. It is cheaper, and later on, you can upgrade.

Factors That Help You Determine When to Move to the Next Level

The size of your jobs trying to sew a design that is over the limits of a home machine could prove challenging. If you find that you use more time re-hooping than the actual time used in embroidery, then it is wise to consider setting up a commercial machine.

Time – in the digitizing for embroidery business, time is of great essence. If you are always late in delivering an ordered product, you should consider upgrading the software or adding a new machine.

Job types- with a digitizing for embroidery business, the size, and variety of jobs make a big difference in your income. Some machines will allow you to switch between embroidering different things like caps to flats. This will help you maximize your time and in return increase your earnings.

Adding Equipment to Digitizing for Embroidery Businesses

If you are an avid apparel decorator looking to get the most out of your investment, then you should lookout for a machine that will help you achieve that. If your job entails doing short runs with a lot of alterations in designs, then 2or single head machines are ideal for your business. If yours is higher stitch count designs, then look for embroidery digitizing machine that will reduce your labour costs while decreasing the space requirements and in the end increase your production. This way, your business wins all the domestic market deals.

It should always be an individual’s decision whether to upgrade. You should always weigh your pros and cons and make an informed decision.

In this industry that is full of experienced business people, it is prudent to provide the highest quality digitized services. This should be coupled with fair prices. To improve your productivity, always ensure there is minimal thread breakage. Always offer vector art conversion which always ensures that logos or any other embroidery digitized designs can easily be turned into a super quality vector format. With this, poor quality files can be converted into very high-resolution vector artwork.

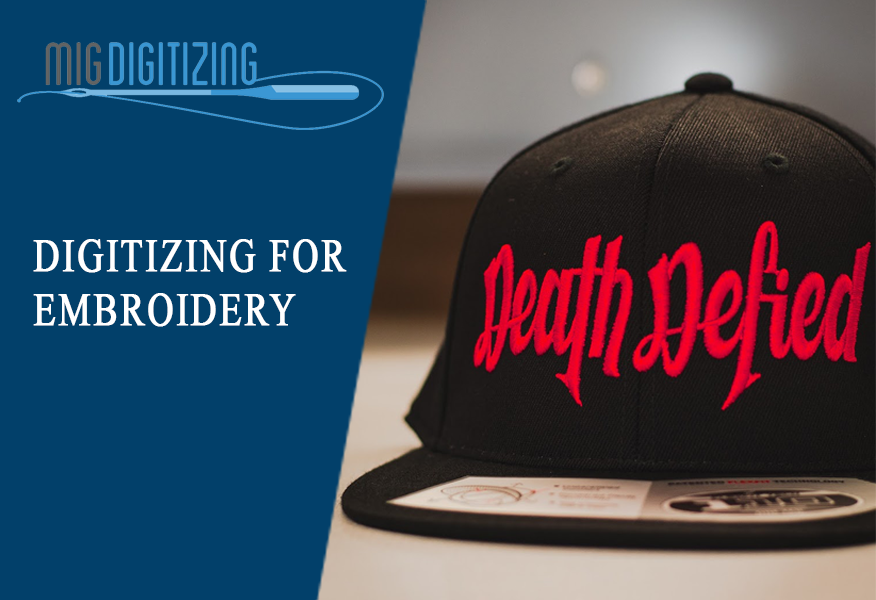

How to Create Outstanding Digitizing for Embroidery Designs

For the best results, splendid embroidery designs and digitizing is required. Without the ideal design structure, the embroidery won’t sew well on the machine. This can impact on the reputation of your business.

What is Embroidery Printing

This is the process of embroidery sewing on a blank garment. It starts with the digitizing stage. You can decide to break a technical design into individual shapes thus making the complete digitizing designs simpler.

You should learn how to incorporate stock designs with corporate logos and produce a customized look. Also digitizing realistic-looking animals, an image, and paintings or, having logos digitized is a great way of creating customized embroidery. This is possible at just a click.

When digitizing you need to import the embroidery file into the embroidery machine in a format, it can read. A knowledgeable digitizer will take into account the number of stitches, their types as well as trims and thread changes. Files given by a client are commonly first digitized for a fee. The software in the machine tells it the needles to use, which way its arms should move when to cut the thread etc.

Various commands will tell the digitizing machine the size of the image you want to work with and the background it will be set in. The image can be cropped, tilted and even changed colour as per customer specification before processing. Good embroidery will avoid loose threads. Use of short stitch is best for lettering while the number of jump stitches (trims) should be kept to a minimum for best result and faster sewing. It is also important to note that the embroidery process is dependent on the material on which it is taking place.