The commercial embroidery services for the caps are completely unique and different when compared with the embroidery services performed on jackets, t-shirts and other accessories. If you are going to follow the tips for the embroidery services for different kinds of headwear’s, you are easily able to save your money and time overproduction and it also increases the level of quality with an improved satisfaction of the customer.

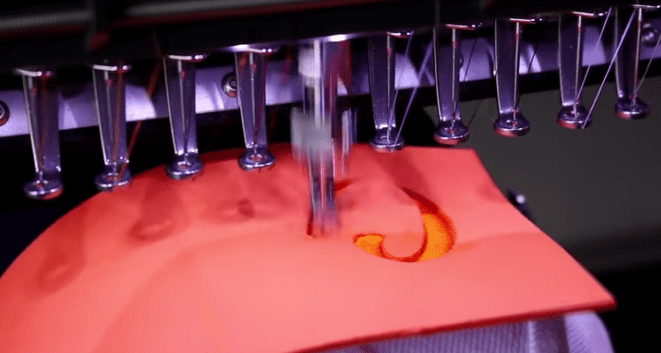

Whenever it is the time for the commercial embroidery services for the caps, it is recommended to be done with care. Such as, if you are going to place the high stitch designs such as 15,000 stitches with the small letters over the front cap, then you are actually going to create a big problem for you. Moreover, this is not a simple thing to dedicate the single-head embroidery machine for working it well for the embroidery over the caps as these embroidery machines work great over the flat surface.

There are the technical issues that can easily be solved if simple and easy rules about the commercial embroidery services for the caps are taken in mind:

Basic Tips for Cap Construction

These days, most ball caps are the six-panel caps with a seam which is running down the front middle. Different methods for the cap construction lead to various issues with respect to the thick and cumbersome seam because of the changing thickness and stiffness of the cap material. The type of design to be embellished on the cap is also dependent upon this feature.

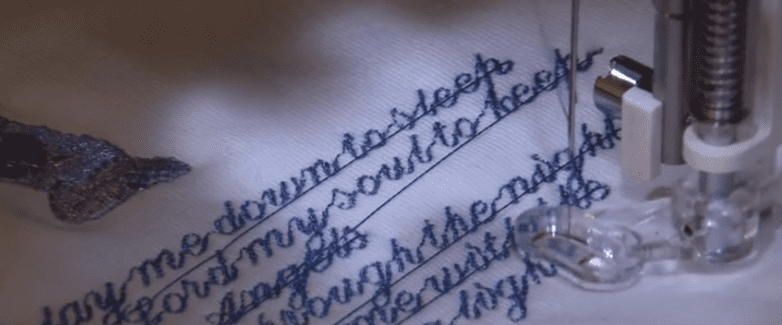

The custom artwork having to outline and small fonts are not good for the cap embroidery thus, it is recommended to add some filled background in for such a situation.

The solid construction should be given to keep the shape of the cap. It can be done with the use of some material such as buckram behind the front panel which can make the digitizing embroidery services on the cap very easy.

When you are working with the unstructured caps, the appropriate backing material and careful hooping are needed. With the use of long and strong backing, you can add more stability to the cap during sewing. In order to get better results, you should also use the clips for cap clamping.

Before starting the process of hooping, the spray adhesives can be added on the cap backing because it can cause the lesser thread breakage.

Small Fonts and Embroidery Details

The heavy and thick seams have been used within the cap embroidery depending upon the details amount. The skipped stitches, as well as needle breaks, can also occur because of the cap logo embroidery having different outlines, lettering, tiny fonts or small details. So, in order to avoid such things, the tightness and detail over the top layer must be minimized. Overall, the 75/11 sharp needles coated with titanium works best for every type of embroidery digitizing services on the cap.

Hooping Tip for the Cap Embroidery

The maximum area of sewing is available in between the 2 inches height and 5.5 inches width for the majority of the cap embroideries. In order to avoid distortion, this is best to keep stitches close to the outer limits.