The process of automating the creation of composite patterns on fabrics with the aid of an embroidery machine is termed embroidery digitizing. This process is used in product branding, logo creation and creating designs on fabrics by cloth designers.

Steps to Creating an Outstanding Design With Embroidery Digitizing

The process of embroidery digitizing is not just about loading the fabric into the machine, and within minutes you have the final design, it involves a series of steps:

Designing the Digital Image

Since the logo or image to be used is digital, there is a need to convert the logo to a digital file that is compatible with the embroidery machine. And if there is the need for a new image, if you have the technical knowledge of using digitizing software, you can design one for yourself, and another option is to purchase online or the local retailers.

you can visit: What You Should Know About Embroidery digitizer in the USA

Design Conversion and Adjustments

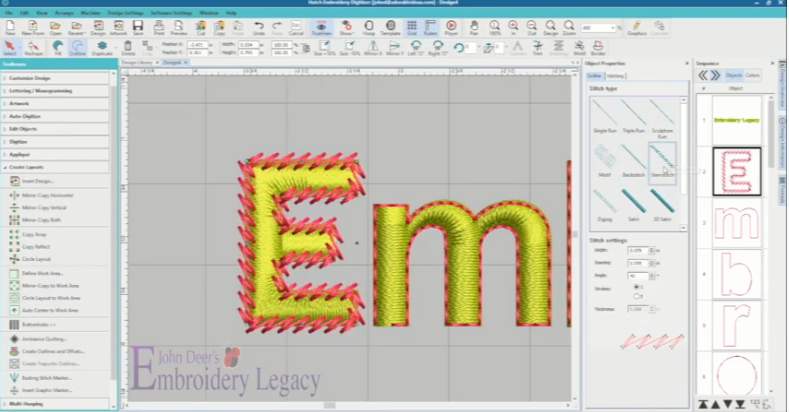

After converting the logo or design to a digital file, the next step is to check if the image requires some editing to suit the design it is intended for and this is done using the digitizing software by a professional embroiderer. The professionals know how to use the software in editing, scaling, cropping, and branding of the design. Another important part of the design they can do for you is to add texts to the image created.

Loading the Digital File Into the Embroidery Software

This is where the use of the embroidery digitizing machine comes in. After editing and the client are happy with the final design, the file is loaded into the digitizing machine. It is imperative to note the type of file that is compatible with the machine in use because the different digitizing machine has different ratings and different file format they are compatible with. The digitized file can be transferred to the embroidery machine using flash drives.

Instructing the Machine on the Path to Be Taken

In embroidering the design, there has to be a defined path to be taken, choosing the right path goes a long way to determining the elegance of the final look. An incorrect instruction of the path leads to uneven designs and with small spaces within the design.

Stitch Selection

There is the need for selecting different stitches for different parts of the design; the stitch that will be used for the text will be different from the stitch that will be used for the logo and even within the logo different stitches may be used. This is to ensure that the stitch used fully brings out the image. Also, the kind of stitches to be used depends on other parameters like the type of fabric the logo is to be used on and so on. Here, the colour and type of thread to be used is also taken care of.

Guiding the Fabric Into the Machine

This step has to be done with the utmost carefulness so that the design will come out without having wrinkles. The different machine has a different method of guiding the fabric into the machine, and the most important part is to make the fabric stable during this process.

Digitizing the Embroidery Design

This is the final and the most important part of the whole process; it usually takes some few hours to get this part done depending on the type and efficiency of the machine you are using. The machine can do separate digitizing for the different part of the design because different parts require different digitizing for a better outcome, this results in better colour separation of the design and also it can digitize the image as a whole, but the design is usually blurred.

Some Common Problems Faced In Embroidery Digitizing

Lettering

The lettering of the logo or text used in the design is very important; it should neither be too big or small. If it is small, you may need to increase the size of the logo so that the design can come out clean and clear. And also, too many letters on design does not bring out a good design; digitized embroidery is different from the conventional logo we are used to, too much lettering makes the design looks rough. There is no need of including your organization email address and phone number in the embroidery.

Too Many Borders

Logo creation in print media is quite different from creating a logo for use in embroidery, the requirements for each of them differs. The use of borders in logo creation is print media is important, but if the same logo with multiple borders is used for embroidery digitizing, the outcome will be of poor quality especially if you are using letters with minimum size.

There is more information out there to make your digitized designs look great. Many professionals have improved on how to make it faster and easier while also putting into consideration the quality of the end product. To save time used in making embroidery digitally, there is a need to work more efficiently; this leads to more profit for the organization. This art is a professional one that needs to be mastered before venturing into it.