The custom hat embroidery is enriched with the skills and it needs expertise. Any mistake or problem within this custom embroidery headwear can cause a great loss as you are going to deliver the less quality work of embroidery digitizing to the client. In order to prevent such problems, it is recommended to avoid some most common problems within the custom hat embroidery digitizing in order to get the top quality embroidery hats.

Hats are usually the most difficult thing for embroidery and thus, there are some important issues that should be handled with care within the custom hat embroidery if you are really looking for the expansion of the business:

Use Embroidery Machine at Normal Pace

-

In order to create the best embroidery on the hats, it is highly recommended to keep the pace of the embroidery machine slow.

-

For the usual design of the custom hat embroidery, the machine running speed must be at least 600 stitches in a minute for the hat frame and nearly 750 stitches per minute for the flat frame. As every design of the hat embroidery is much different from the other, this is just a rough idea to keep your machine pace according to it.

-

If you have some complex, small or complicated details you have to present then it is most recommended to keep the speed of the machine slow.

-

If you have some complex design then the speed of the machine must be at least 550 stitches in one minute for the hat frames and at least 650 stitches for the flat in order to improve the stitching and registration.

-

With the slowdown of the embroidery machine speed, you are easily able to control the expense by simply avoiding all the wastage by getting the right embroidery in your first instance.

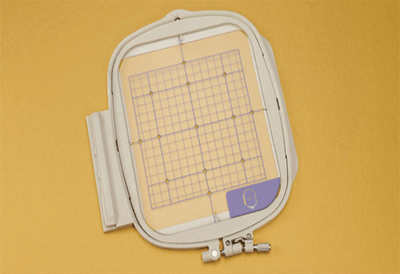

Perfect Hooping Method

-

Inappropriate embroidered products hooping particularly hats can cause the bad quality of the embroidery.

-

It is recommended to use the Durkee hoops as they can be easily placed straight and within the centre.

Watch the Tension in Thread Appropriately

-

Within the custom hat embroidery, one of the most common mistakes is the tension in the embroidery thread. You should run the regular tension thread checks on a daily basis.

-

The appropriate tension within the thread offers tight and nice embroidery with most crispy logos and letters that offer top quality hats.

Dealing With the Bobbin

-

Whenever you are going to change the bobbin, it is mandatory to consider the tension in the thread.

-

Either too tight or too loose bobbin can affect the custom hat embroider designs.

-

In order to create a consistent and top-quality hat embroidery, it is recommended to not overlook the bobbin.

Change the Needles Regularly

-

It is recommended that the embroidery needles of the hat embroidery machine must be changed enough for quality maintenance.

-

The changing time of needle is dependent upon a large number of factors particularly, needles quality, material, and fabric used, running time of machine etc.

-

It is best to keep a check on your needles each week and if needed then change them.