It is much worthy to say that the needles are the most important part of machine embroidery. Selecting the best needle from a large number of choices is very confusing. This is why we have come up with some quick tips and guide to cover some important things you must consider while selecting the embroidery needle for the next digitizing services project.

Before going to select the needles, it is important to have a look at its specifications and consider the fabric type, thread, and stabilizer used for your work. Some important factors are the determinant of the embroidery needle size for the project. So, with the use of the right needle, you are going to eliminate the breakage of thread and your design of embroidery is also going to run smooth and clean.

Difference Between Sewing Needles and Machine Embroidery Needles

When we talk about the machine embroidery digitizing services, there are large numbers of needles that are made specifically for such machine embroider and they are known as the embroidery needles.

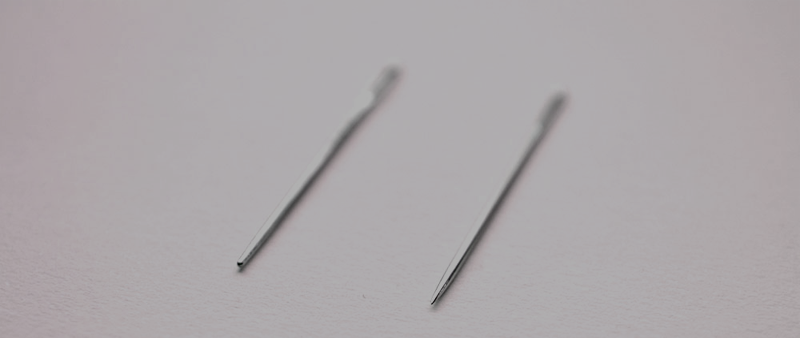

Although, both terminologies can be used for the embroidery needles the major difference between these two needles is the eye shape along with scarf shape. The machine embroidery needles carry long eye and they have a sharp scarf which is suitable for the delicate and soft embroidery threads.

-

Points

One of the highly used embroidery needles carries a universal point which has the rounded tip. This point is suitable for the majority of fabrics as well as stabilizers. The exception to this point is that if you are going to use the fine stabilizer which resembles plastic film then you have to use the sharp point needle such that it has the ability to pass through the stabilizer.

-

Size

The embroidery needles largely vary in their size between 70 to 110 mm. the lower needle size refers to the finer needle. The size of the needle you are looking for is dependent upon the type of stabilizer, fabric, and thread that you are going to use.

-

Type

If you have a tough project then the best thing is to use the titanium. But if you are going to use the tough or dense material then your needle can easily penetrate fabric without even losing its shape. This actually lasts more than 3 to 5 times when compared with the regular chromium plated needles.

Select the Right Needle

The most important thing that you must do before starting shopping for embroidery needle is that you must look at your embroidery machine user manual and look for the type of needle which is going to fit in your digitizing services machine.

Before the start of the embroidery project, you have to consider the embroidery machine needle specifications along with the fabric weave and weight, stabilizer type and thread and the density of the design of embroidery that you are going to work on.

It is the general rule that you should use the large needle for the heavy fabric and the lighter fabric needs a small needle.