In the digitizing industry, the most common issue is thread breaks. If you're a beginner or even a seasoned quilter, you may have experienced the issue of splitting those bulky threads. It can make you want to throw your hands in the air and scream, "Why is my thread on the sewing machine still breaking? What is the problem and do I troubleshoot it? Well, this is a common but frustrating issue. It prevents everyone from completing a piece you're passionate about, including the expert sewer.

However, there are some ways to stop these problems from occurring occasionally. MIG Digitizing is the leader in the digitizing world. We have professionals who are fully aware of the nitty-gritty of the embroidery digitizing process.

We will discuss with you all the major thread breaking problems. Why they occur and what steps can we take to reduce thread breaking in the embroidery digitizing process.

It's painful if your thread keeps breaking. And it gets more irritating and boring to reprocess and patch the upper thread on your embroidery machine.

Understanding the reasons why the thread break issue occurs will help you identify the problem quickly, solve the problem. It will result in completing your task in a smooth and effective way. Let’s talk about what the thread break causes, errors, and its preventions.

Thread Break Errors

Check The Thread

If your upper thread breaks, the issue might be that it is not properly installed in the sewing machine. Familiarize yourself with the upper thread strand and interact with every aspect of it. You need to ensure that the top thread is correctly installed at each point by following the strand. It will help you to narrow the cause of the thread breaks and ensure that they will work in a smooth way.

There are pitches set to zero in the embroidery details that can be a problem sometimes. You need to check the data to make sure all null pitches are extracted.

The thread you are using should have strong reliability to make perfect stitches. If the thread you use is old, then it can cause a thread break during the digitizing process. Therefore, it is smart to buy a high-priced thread that is strong, durable, reliable, and long-lasting. To spend a couple of dollars more won’t break the bank, but it will surely decrease the risk of your thread breaks.

Check The Pressure

Once you have checked the upper thread. Make sure that the pressure is not too high. If an error occurs, the upper thread will not work properly, or it will break quickly. Check the upper strand tension and make adjustments using the knobs on the sewing machine accordingly. To make it simple, the higher the number on the dial, the stronger the voltage or pull for the thread.

Check The Thread Spool

Check the thread spool itself. Make sure that it is properly installed in the embroidery machine. Ensure that the right spool cap is in place. It needs to coordinate with the thread spool you are using means that there shouldn’t be a size mismatch. It is important to make sure that the cap of the spool is right. It should not be too small, or too large or the top thread may break.

Check The Needle

Check the needle. It should be inserted in an exact way. The needle's flat side should be away from you. You can tighten the needle clamp with the help of a screwdriver. You don’t have to panic as you will find instructions on every sewing machine on how to install and take care for each part.

A broken or bent needle can also create hindrance to the top strand when you stitch. Proper embroidery needlework includes a needle that has no twists, dents, chips or breaks. We all tend to keep the needle in the machine until it is absolutely necessary to replace it, but be sure to check the needle itself for any issues that might cause the upper thread to break every now and then.

The startling movement snags and splits the thread, so make sure the needle is straight up and reaches the right part to make perfect stitches.

Check The Tension

Tension is another cause that can lead to thread break in embroidery digitizing. You need to check both the upper tension and the lower tension. To achieve similar stitches, the top and bottom threads should have the same tension. Depending on the embroidery machine you have, the lower strand can be changed by hand if appropriate. In addition, older machines will need upper and lower strands to be calibrated to the appropriate pressure. It is due to the fact that the older machine does not have automatic adjustments.

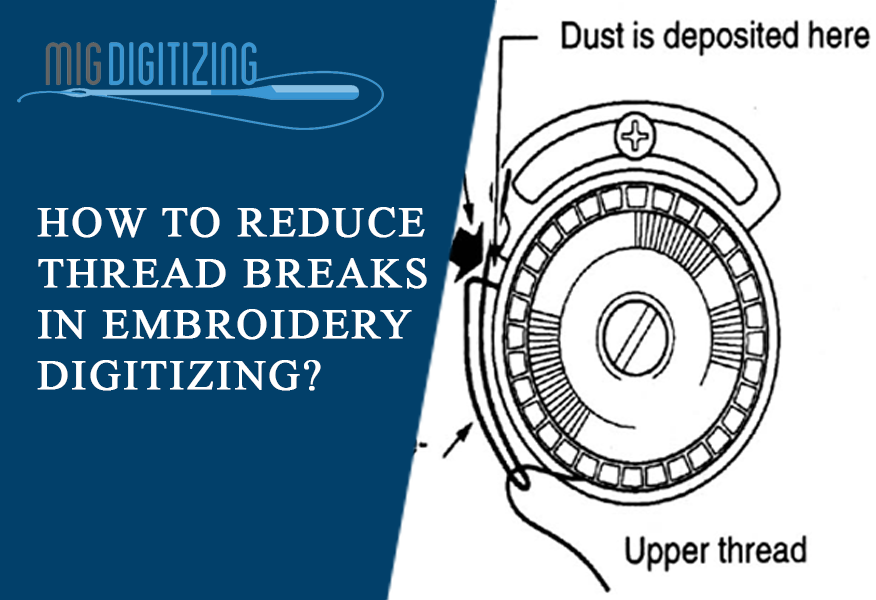

Check The Bobbin

Bobbin can also be a factor for thread breaking. Check that the bobbin thread is placed in a proper way. Make sure that the thread is wound evenly in the bobbin case. It’s a rabbit and turtle race where you need to be a turtle, slow and consistent.

A specific bobbin is used for each kind of embroidery machine. You should correctly match the bobbin with the embroidery machine for the best quality stitching and quilting. By doing this, the risk thread break decreases.

Be Clear With The Pitches

In embroidery digitizing, every stitch counts. You need to be attentive in making stitches. Be it a large stitch or a small one; every stitch has to be on the exact place where it should be. So, check that there are no stitches with extremely small pitches in the embroidery details. It can be the cause of a thread break. Check that there are no stitches with extremely small pitches in the embroidery details. This might be the cause of the upper thread problem with the tiny stitches you should erase.

These are some of the major issues for thread breaks in an embroidery machine. Keep in mind that there can be bigger issues that may need to be fixed by a specialist. If your needle-threading system breaks, the top thread will definitely break. So, if there is such a similar issue, then you need to service your machine.

Some Key Tips To Fix Problems

As said above, if you are facing a bigger issue, your embroidery machine may need a service. However, here are some tips that will help you to troubleshoot and fix the major issues.

Make Sure There Is A Smooth Thread Path

It is necessary to clear the thread path. Clear your direction to the line. Take the thread out and follow the path. Move your hands slowly along any big points like the throat plate or the bobbin. Make sure there are no threads or needles that block the path of the thread or interrupt the movement.

Only Use High-Quality Thread

For the project you are working on, make sure to use the right line. The thread thickness varies depending on what you knit or quilt. Also, make sure you don't use old or old thread. To avoid this, occasional sewers date the thread spool to ensure that the thread quality is the best. By growing a threaded end in each hand and pulling, you can check the thread itself. Throw it out if the thread breaks. Storing the thread correctly would also ensure that you get out of the thread as soon as possible.

Always Use The Right Needle

It is as important as any other factor to check the needle. Because of the material and tool, you are using, the use of the right needle defines the quality of stitches. A thinner needle for thin or delicate fabrics is needed, for example, and a thicker needle for heavier fabrics.

Don’t Forget To Check The Bobbin

Check the bobbin and case for any bits flying away from earlier quilting projects. You should turn your machine upside down and shake it a little to clear up any pieces that may be trapped in the case of the bobbin.

Check The Throat Plate

Test the throat plate. A throat plate is often referred to as a needle plate. Make sure that the throat surface on the computer is properly in place so that the needle does not touch the surface. Sadly, people often ignore to check this issue and tend to have a broken needle plate, and end up in having thread break problems.

To sum up, we can conclude that to master embroidery digitizing; you need to educate yourself with every single part of the machine. Study the parts for each wonderful stitch and how they work together. Through learning about each part of the machine and how to take care of it, you never have to ask yourself again "why is my thread breaking on the embroidery machine?"

If you still have any trouble with the embroidery machine or any issue related to it feel free to take our help. MIG Digitizing endeavour to give its customers 24/7 customer support