Screen Printing and embroidery are two different terms. Both terms have different meanings. The interesting part is that they are linked to the same industry (any industry dedicated to decorating clothing and apparel).

However, you need to know the difference between screen printing and embroidery digitizing. In this article, we will educate about both the terms.

What Is Screen Printing?

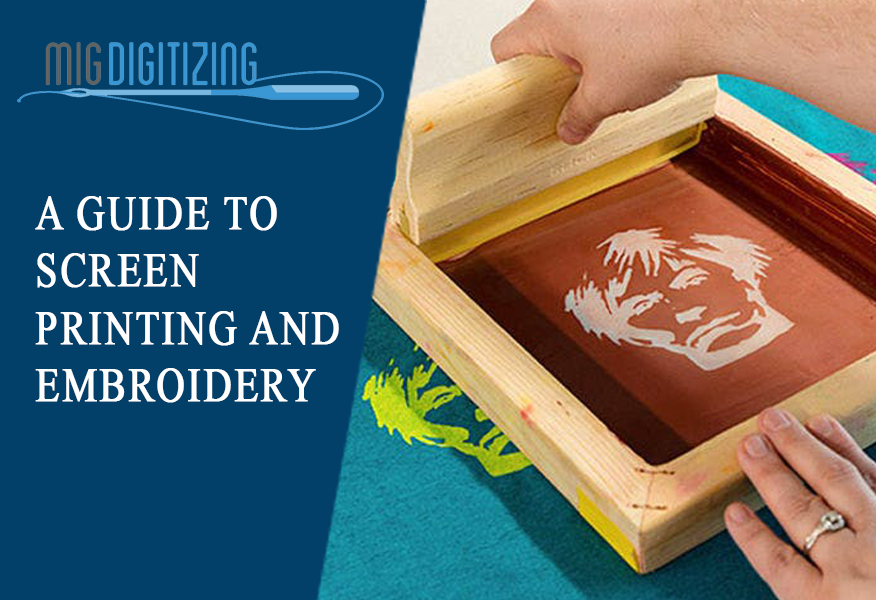

To understand screen printing in a simple way, it is the process to transfer the designed image (stencilled) to the desired fabric or surface with the use of a particular screen (usually a mesh screen). The two most important types of equipment for screen print are ‘paper’ and ‘fabric’. But, the process is not restricted to only fabric and paper.

The Process Of Screen Printing?

The basic method or process involves creating a stencil design on the mesh screen. After that, we have to push the ink to create a design on the desired surface. Through screen print, it is easy to make designs that are difficult and complex.

You may hear the word ‘silk screen printing or silkscreen’. Don’t be panic! The process is similar to the basic screen print. The only difference is that you can block the ink to certain areas with the help of a blocking stencil.

In technical terms, screen printing is about using the right ratio of the colours to the items that you want to print. The ink, shade, and colour depending on the complexity of the design. If there are multi-coloured items than it is important to apply colours in individual layers by the use of a separate stencil for each ink.

To dig deep, we will take a look at some important factors like vector conversion, printable files, high-resolution images, and printing types on t-shirts.

Vector-Conversion

Vector graphics is an art. It involves creating digital images using vector software. All we need is to align the right lines and shapes to make a two-dimensional image. And guess what, you can enlarge the image as much as you want. The image won’t pixelate no matter how big the print is. There is a series of paths that are made on different vector software such as Adobe Illustrator. We can also convert the vector image into a raster image.

Printable Files

After all, we need a suitable file format that is readable for the screen print machines. There are different file formats for screen printing like JPEG, PNG, EPS, and much more.

A big plus for heading to the screen print designs is that the high-resolution images can be easily converted to the jpeg format without any customization.

What Are hi-res Images or High-Resolution Images?

Hi-Res or high resolutions images are those images that have denser image quality. An image is made of tiny dots called ‘pixels’. To make it simple, low-resolution images have fewer pixels whereas high-resolution images have more pixels. As the high-resolution images are dense. That’s why they don’t pixelate when we enlarge them.

On the contrary, low-resolution images are not dense. We have to make appropriate paths so that they are compatible with screen printing machines like the F2C Pro 6-in-1 Combo Heat Press Machine and SCHZOND 1-Color 1- Station Silk Screen Printer.

Although screen prints are made on a variety of different materials and products. However, the most common type of screen print is a t-shirt. There are different types of methods for screen print that are listed below.

Types Of T-Shirt Printing

1. Heat Transfer Vinyl

2. Computer-aided Design (CAD) Cut Printing

3. Dye Sublimation

4. Heat Press Printing

5. Screen Printing

6. Direct to Garments (DTG)

7. Dye Sublimation

Where Is Screen Printing Used?

Screenprint designs are used on materials like t-shirts (we will talk about types of t-shirt printing below in the article), uniforms, pens, bags, mugs, and much more. With the help of specialized inks, you can also print the designs on other surfaces like plastic, wood, glass, and metal. The main benefit of using screen print over embroidery is that you can create high-resolution images with complex details on them. Therefore, it is smart thinking to go for screen print for high-end designs.

The Difference Between Screen Print And Heat Transfer

In heat transfer, the design is made through a specific heat-adhesive. A heat press is applied to the tracing paper. The heat-adhesive reacts to the heat and sticks on the desired surface. Heat printing is easy and cost-effective. The downside is that heat printing solely depends on the material. Therefore, the quality of the final product can be drastic.

Whereas, screenprint is more convenient for complex designs as the chances of having low-quality outcome are fewer.

What Is Embroidery?

Embroidery is a simple process where stitches are made by a thread to the custom product. The tradition has been in the industry for a long time. The stitches were made by hands. Now, the companies use modern embroidery machines and software to perform the task.

Embroidery Designs And Price

We can do embroidery on almost every clothing and apparel like t-shirts, jackets, beanies, gloves, towels are to name but a few. The price of an embroidery design depends on the number of stitches and the number of items or products.

Aren’t Sure Which To Use?

Not sure which to use - screen print or embroidery. Here, at Mig Digitizing, we have got it all sorted for you. Give us your artwork or contact us. We will inspect and examine the scenario. We will give the best advice and services at market-competitive rates.