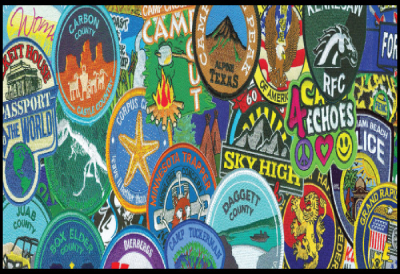

An embroidery patch is a design that is made using thread and fabric backing. To make patches is an art. The tradition has been in the fashion industry for ages. The advent of modern machinery and software has turned the tables. It has made it easier for companies to make embroidered patches. The purpose of using these patches is simple - to make clothing and apparel beautiful and charming.

You will see these patches and designs on military personnel uniforms, firefighters, paramedics, and police officers more often. These patches are also known as ‘cloth patches’.

In this article, we will take a deeper look at embroidery patches.

The Process Of Patches Embroidery Designs

The process is simple and easy. It involves making the patches through fabric-packing. The patches are sewn through different threads. The modern methods are implemented that involve iron-on, heat adhesive, and dryer.

To make it simple, we can define the process in three major steps.

-

Fabric and stabilizer.

-

The making of a fabric patch

-

Linking the fabric to the cloth

Fabric

The quality of the fabric plays a vital role in making a patch. Therefore, it is recommended to use high-quality fabric material to get the best results.

If you want to make large badges with or without the embroidery artwork, then it is better to use the Tackle Twill for badges. This fabric is smooth and strong and has two-different sides giving you the opportunity to make designs on either side depending on the requirements.

The other fabric you can use is a good-quality felt. Felt is different from other fabrics. It consists of steel wool rather than clothing material like wool, cotton, or silk. You need to make sure that you choose the right thickness of felt and it should be non-elastic. Elastic felt can lead to poor results.

You can also use the structured fabric. This fabric doesn’t have any complex design patterns. The texture of the structured fabric is made with different materials like wool, cotton, silk, viscose, and polyester using different weaving techniques. It can enhance the performance of the fabric.

Stabilizer

The fabric that we use for a patch is not hooped from top to bottom. Only the upper surface of the stabilizer (an embroidery machine that helps in supporting the fabric during stitches) is hooped. It is important to keep the stabilizer invisible around the edges. The solution for this is these two methods:

-

Water-soluble stabilizer

-

Tear-away stabilizer

The Making Of A Fabric Patch

You need to have precise knowledge to make a fabric patch (also known as an embroidered patch). To make it easier to understand, there are four steps to create a fabric patch.

-

First, you need to make a placement stitch. It will give a position and will make an outline for the pre-cut.

-

Then comes the tack down or zigzag stitches that strengthen the patch.

-

A cut line is made for the borders that will fix the patch.

-

At last, we have to make a cover stitch for the border. The size is usually between 2.5mm to 6mm. The process is also known as ‘merrowing’.

A similar technique is used to create applique designs.

Linking The Fabric To The Cloth

You can link the fabric in two ways. Either you can use the iron method or the heat press or you can go the specified glue to link the fabric.

If you are using the heat press method, it usually takes two seconds at a temperature of 200 degrees. Yet, the temperature can vary. For glue, you can use any super glue like UHU, Patex or others. It is recommended to use the heat press method to attach the fabric. With a glue, the fabric can become loose after repetitive washing.

If you are not satisfied with any of these methods, just sew!

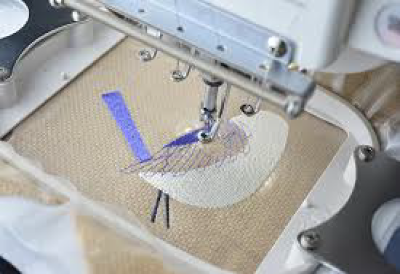

Patches Embroidery Machine

The type of machine depends on your business. If your business is small, you can use a small machine like the memory craft embroidery machine.

However, for a commercial purpose, where a Custom Patches variety of patches are made, then you need a powerful and reliable machine to perform the task. Some considerable machines for patches are:

-

CAMFive CFSE-DM1501

-

Janome MB-4S

-

Brother PE770

-

SINGER 20U109

-

Janome MB-4N

-

CAMFive CFSE-CT 1502-5D

Have Any Questions? Reach Out To Us!

This is the process of patches embroidery. Use these steps to avoid problems and minimize your difficulty. This way, you can grow your patches’ business at a faster pace! If you are facing any issue or trouble, you can contact us. Mig Digitizing offers the best embroidery patches online services at cost-effective rates.